Shop Menu

🚀 5% OFF Your First Order. Use Code FIRSTORDER5 🚀

Are your Ratchet Straps compliant?

Did you know that if your ratchet strap has a nick in it or a slight tear, it is no longer compliant and MUST NOT be used and discarded?

I mean this seems pretty straightforward! But you would be surprised how many times we have seen trucks pulled over with lost loads and busted straps that could have been avoided.

There are some telltale signs that your ratchet straps are starting to wear out, look for:

- Abrasion

- Broken threads

- Burns

- Caustic burns

- Crushed straps

- Cuts

- Embedded objects

There also must be safety ratings & and testing tags stitched into each component of the ratchet and strap. If these are absent or worn, the strap MUST NOT be used.

Do not be caught out with non-compliant or faulty straps. Not only could you lose your load but you could lose your license! Poor quality ratchet mechanisms may also give way or seize up, make sure you don’t sacrifice quality for price this hay season!

We see a lot of cheap ratchet straps on the market, the old saying goes, you can’t have a low price and a high-quality product.

There is a report from the National Transport Commission published in 2018 that is close to 300 pages…it’s a bit of light reading, you can access it here.

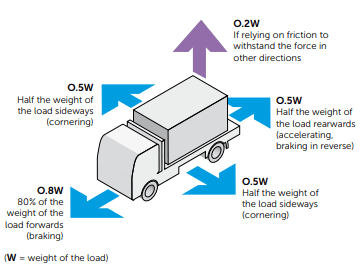

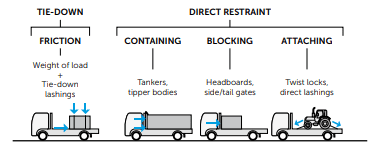

The long/short of the ratchet strap section is as follows:

What are Ratchet Straps?

Ratchet straps are tensioned using either attached clip-on sliding winches, in-line tensioners or geared winches.

The amount of tension produced by a truck winch or hand ratchet depends on the length of the handle, how large the diameter of the webbing spool becomes during tightening, and the number of ratchet teeth.

Hand ratchets that operate by pulling the handle downwards will normally produce much more pretension (600kgf) than push-up ratchets and standard truck winches.

How do I know if my ratchet strap is compliant?

When assessing the serviceability of webbing and attachments in relation to AS4380, if any of the following conditions exist, replace the webbing or attachment:

- Webbing weakened by 10% or more of its original minimum breaking strength by any of the following:

– wear, damage or stitching failure caused by excessive loading, knotting and bending

– exposure to chemicals, including acid and alkaline solutions and organic solvents

– exposure to high temperatures

– prolonged exposure to sunlight or ultraviolet light (fibres will appear hairy). Webbing that appears hairy or furry indicates the webbing is worn, and may indicate loadbearing fibres are broken. - Webbing repaired in a manner not approved by the manufacturer

- Any attachments (tensioner, hook and keeper, etc.) weakened by 10% or more or prevented from functioning by wear, damage or corrosion.

To purchase our BLUE TONGUE LOAD RESTRAINTS ratchet straps click here