Shop Menu

🚀 5% OFF Your First Order. Use Code FIRSTORDER5 🚀

Thermal Insulation Blankets

What is Thermal Insulation?

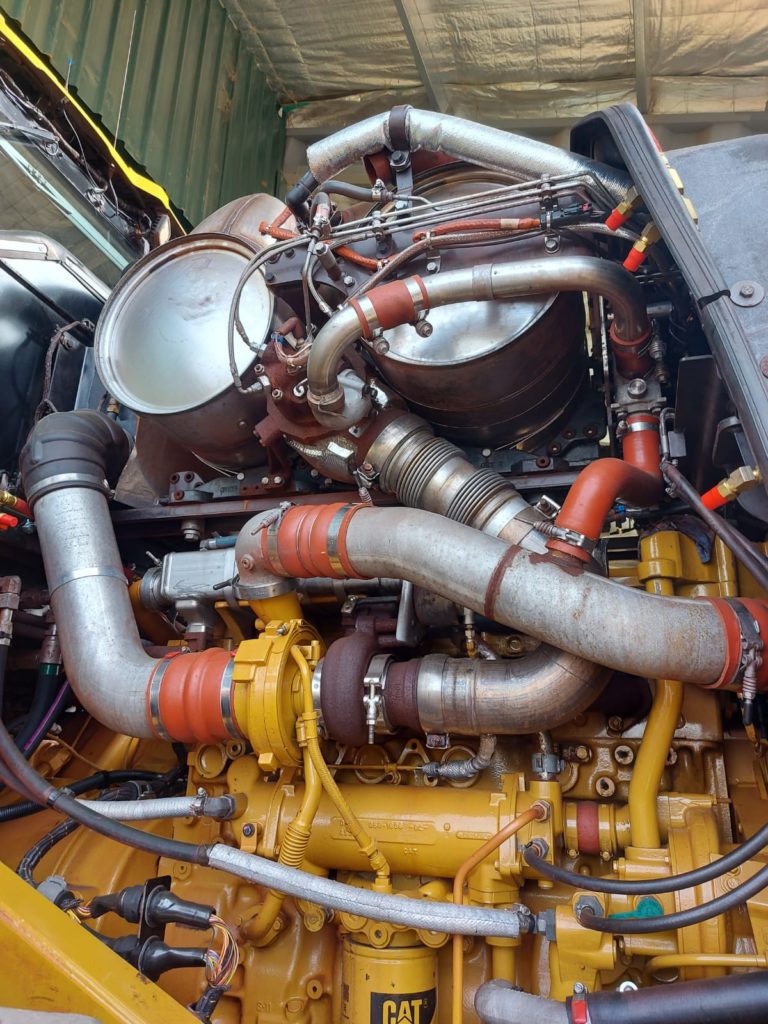

Thermal Insulation Blankets (Lagging) are a Mine Site requirement to control surface temperatures of manifolds, turbos, exhaust pipes and mufflers.

There is often confusion about the purpose of Lagging, a lot of people still believe that it is so operators don’t burn their hands if they touch an engine bay. The real purpose of Lagging is to keep engine bays cool so the machine doesn’t overheat.

Our MineBase Lagging also acts as a protective shield if a fuel line bursts and spills oil throughout the engine bay.

After trialling and testing materials and methods from all over the world, we have produced a solution that balances the optimum levels of Heat Resistance, Thermal Conductivity, Abrasion/ Vibration Resistance, Fluid Repellence, and Incombustibility.

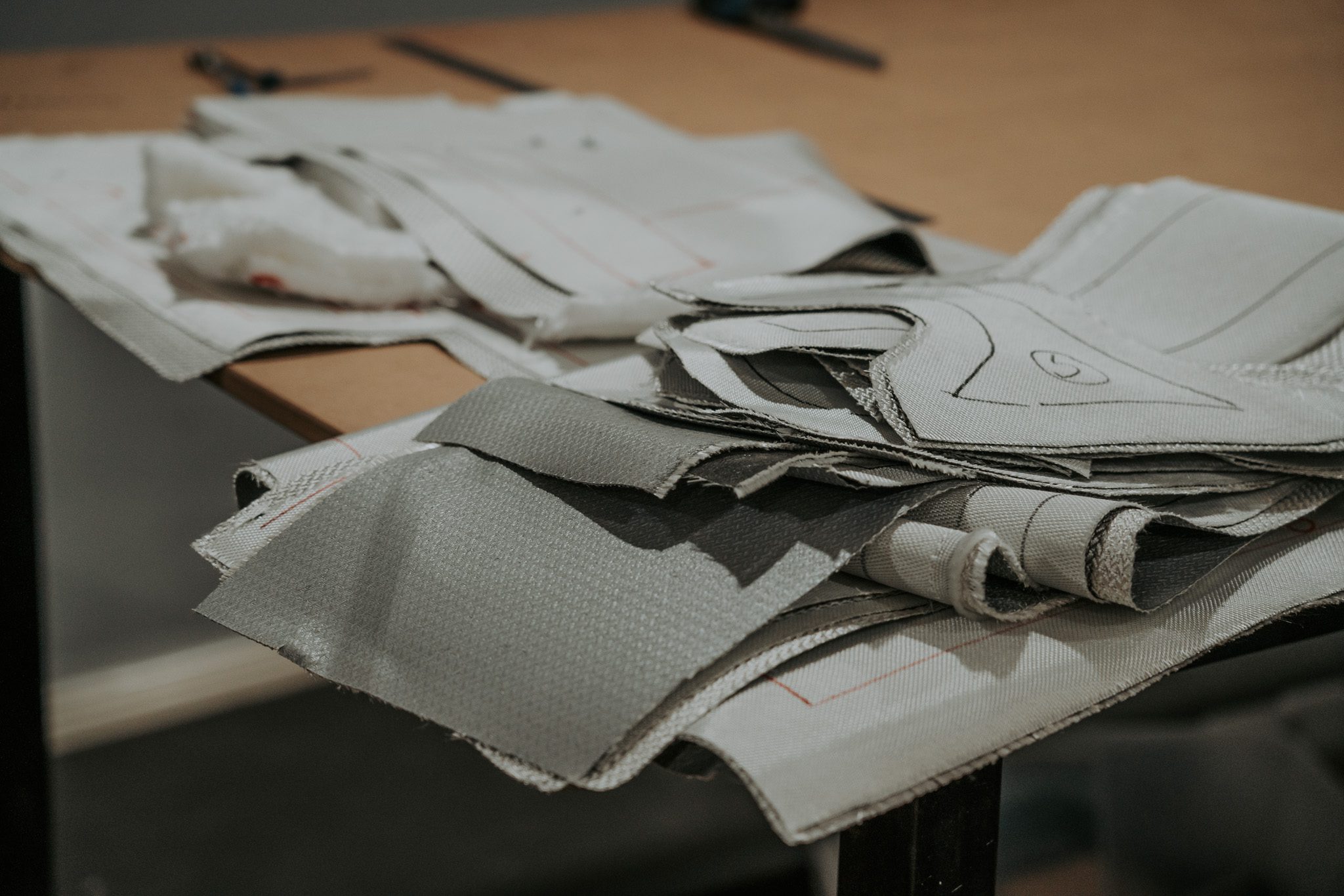

Thermal Insulation Blankets are made up of 3 key parts.

Hot Face

The use of aluminium-coated silica glass rather than mesh has proven very successful. It does not transfer heat in the same way mesh would, and heat is reflected keeping the outer layer cooler. Non-permeable aluminium material prevents the absorption of flammable liquids that would otherwise become a potential point of combustion. It also allows better fitment of the blanket and reduces the risk of creating a power short or conduction point.

The Hot Face layer will comfortably withstand a continuous temperature of 750°C

Insulation

The middle insulating layer made from 96% silica fibres is a poor conductor of heat. We can add/ remove layers depending on the engine.

We can achieve your desired surface temperatures to keep them below fluid ignition points and prevent burns.

Our wire-reinforced inner layer will withstand the vibrations of the idling engine. This keeps the insulation fibres contained and stops the blankets breaking down meaning they won’t require replacement as often.

Cold Face

The outer fabric layer is coated on both sides with silicone. Even if the outside suffers wear, there is a second line of defence against fluids. You can’t see it but the hot face layer is also coated with silicone on the inside.

This layer repels flammable fluids and directs them away from the hot parts of the engine. Without this, the oil can become absorbed into the blanket becoming a potential fire hazard.

Australian Made & Owned

Advance Global has been licensed by Australian Made Campaign Limited to use the Australian Made, Australian Grown logo on the products listed below in accordance with the AMAG Logo Code Of Practice: Licensee ID number: 16687

Benefits of MinebAse Thermal Insulation Blankets

Using our MineBase Thermal Insulation Blankets on your mining equipment has many important benefits.

Being persistent with quality gives our customers the peace of mind they have selected the safest product for protecting their assets and their people.

Case Study

We have worked closely with a Mine Site in NSW that had issues with fires underground due to exhaust insulation not being sufficient to their needs. This particular site was reporting in excess of 4 incidents per year in the beginning.

Since MineBase has been involved there have been no reportable incidents directly relating to fires started underground from Lagging not being to standard.

MineBase continues to do quarterly auditing and maintenance on all insulation products and continuous QA measures are put in place to ensure the standard has been kept to a maximum.

Product Testing

We are continually testing our products with cutting-edge technology in thermal imaging and temperature testing.

Heat Testing

We regularly test new and different products and materials in the marketplace to ensure we are providing the best possible solution. The black MineBase insulation has proven to reduce the external temperature by 24% on average (Photo 1 below). The silver material with an inner and outer layer of mesh fared the worst as the mesh became a heat conductor over a period of time (Photo 2 below).

Oil Testing

We conducted an experiment on the repelling properties of different types of insulation which confirmed what we believed our unique safety edge to be. Photo 3 (below) shows the inner layer of an alternative blanket style has absorbed the oil and potentially could become a hazard. The MineBase product has repelled the oil. Photo 4 (below) also demonstrates the repelling properties of MineBase insulation.

Ceramic Coating & Thermal Insulation

MineBase provides a proactive approach to thermal insulation inspections. This includes a comprehensive thermal image with temperature logging, alongside a still real time photo to highlight any areas of potential threat or degradation.

This can be particularly misleading in infrared thermal imaging devices as the ceramic-coated surface will reflect the infrared beam from the testing device and therefore give a false reading. Download the Thermal Test Images here.

Frequently asked questions

Not only does Thermal Insulation protect operators and fitters from exposure to high temps but it also reduces temperatures in high-risk areas, such as engine bays in close proximity to fuel and oil lines. Our Insulation has an outer layer that repels any flammable liquids from reaching ignition points. e.g. when a fuel/hydraulic line bursts and sprays onto a turbo or manifold which is particularly dangerous in an underground mine.

Yes! We prefer to install as we are trained in this field and have the right tools for the job. This allows us to ensure there are no corners cut with our own in-house Q.A. process.

Yes we can! We keep a very large library of designs on hand and have the capabilities of measuring all types of equipment to suit your needs.

Our average lead time from measurement to installation is 5 working days. Machines that we have already measured generally take 5 working days. This depends on the location, workload and machine components required.

It depends on what conditions or environment the machines are working in. e.g., underground mining where machines need to be washed down in constant sunlight etc. However, we have had machines in these particular conditions with Lagging still in perfect working order for over 4 years. Exhaust leaks will shorten lifespan.

No, our Insulation uses silica glass, which unlike fibreglass; when installed correctly by one of our trained technicians, keeps turbos and other exhaust components at an even temperature for more regular periods, which has been proven to increase their longevity.

If you have any questions regarding our Thermal Insulation Blankets you can send us a message or call us on 1800 624 088.